Custom Concrete Counter

Design

This project required a custom concrete countertop and shelves. My goal was to match an existing unit I had created a year and half earlier. I needed to source matching high grade concrete and the same plywood to make the match flawless.

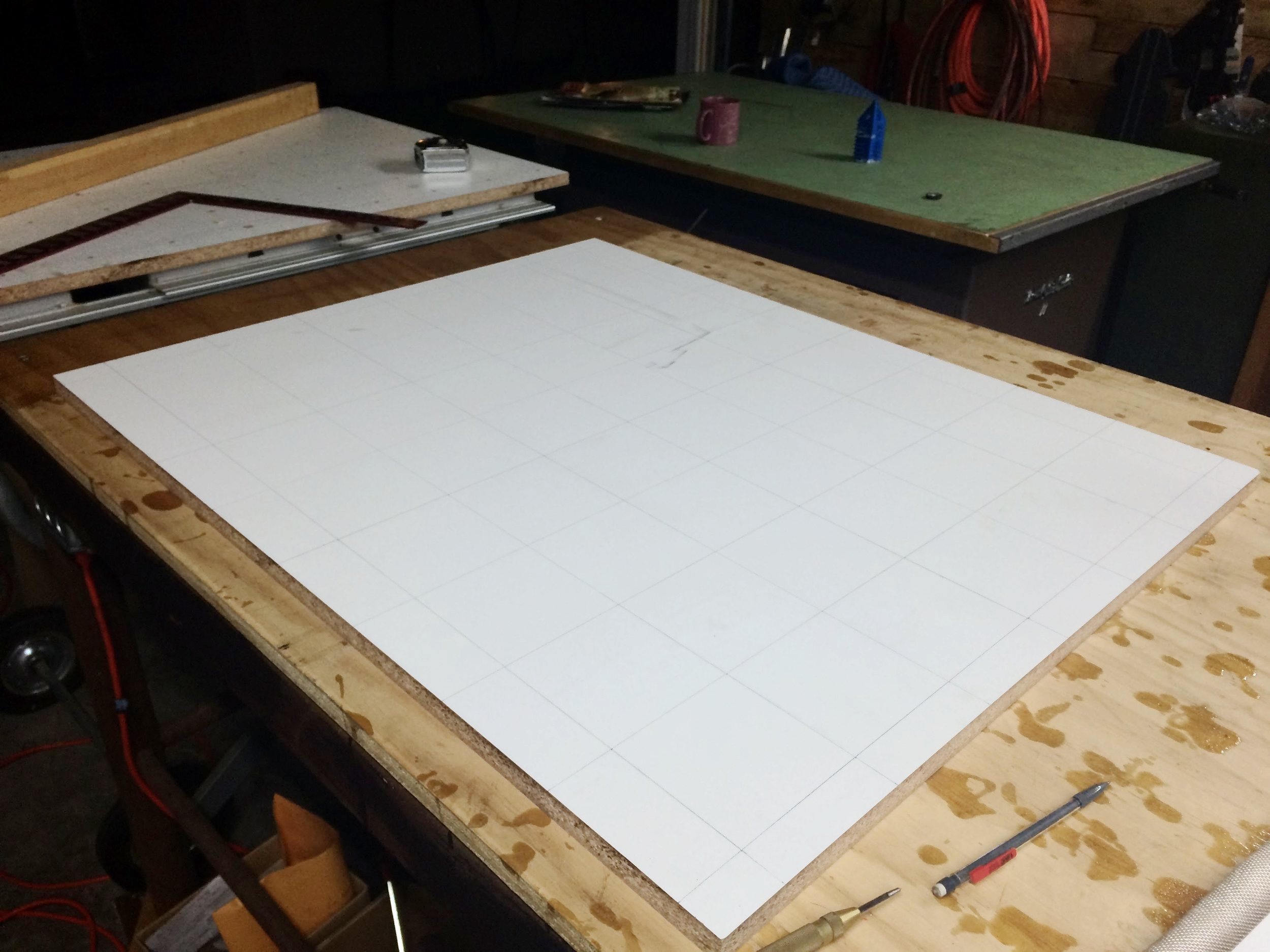

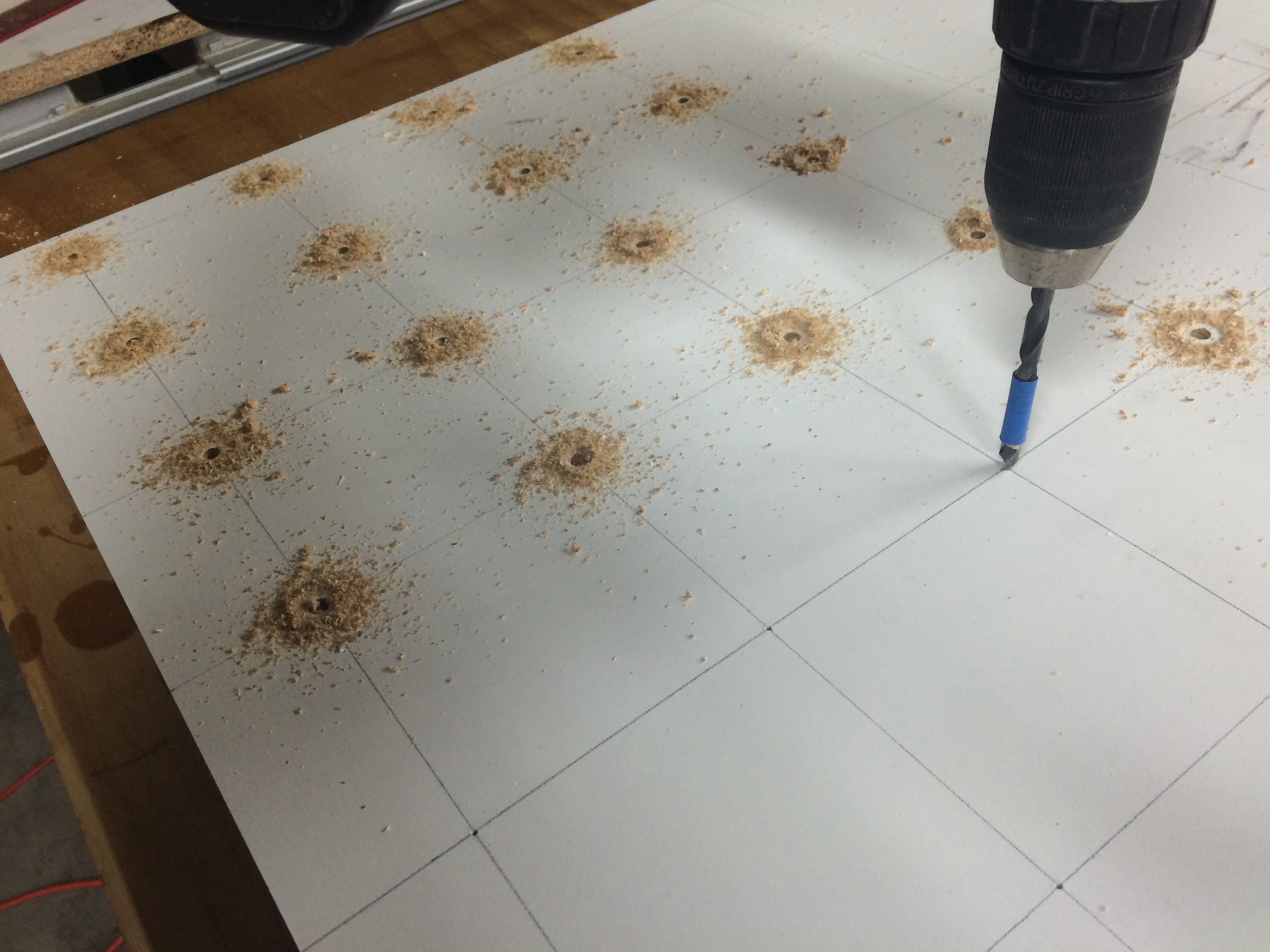

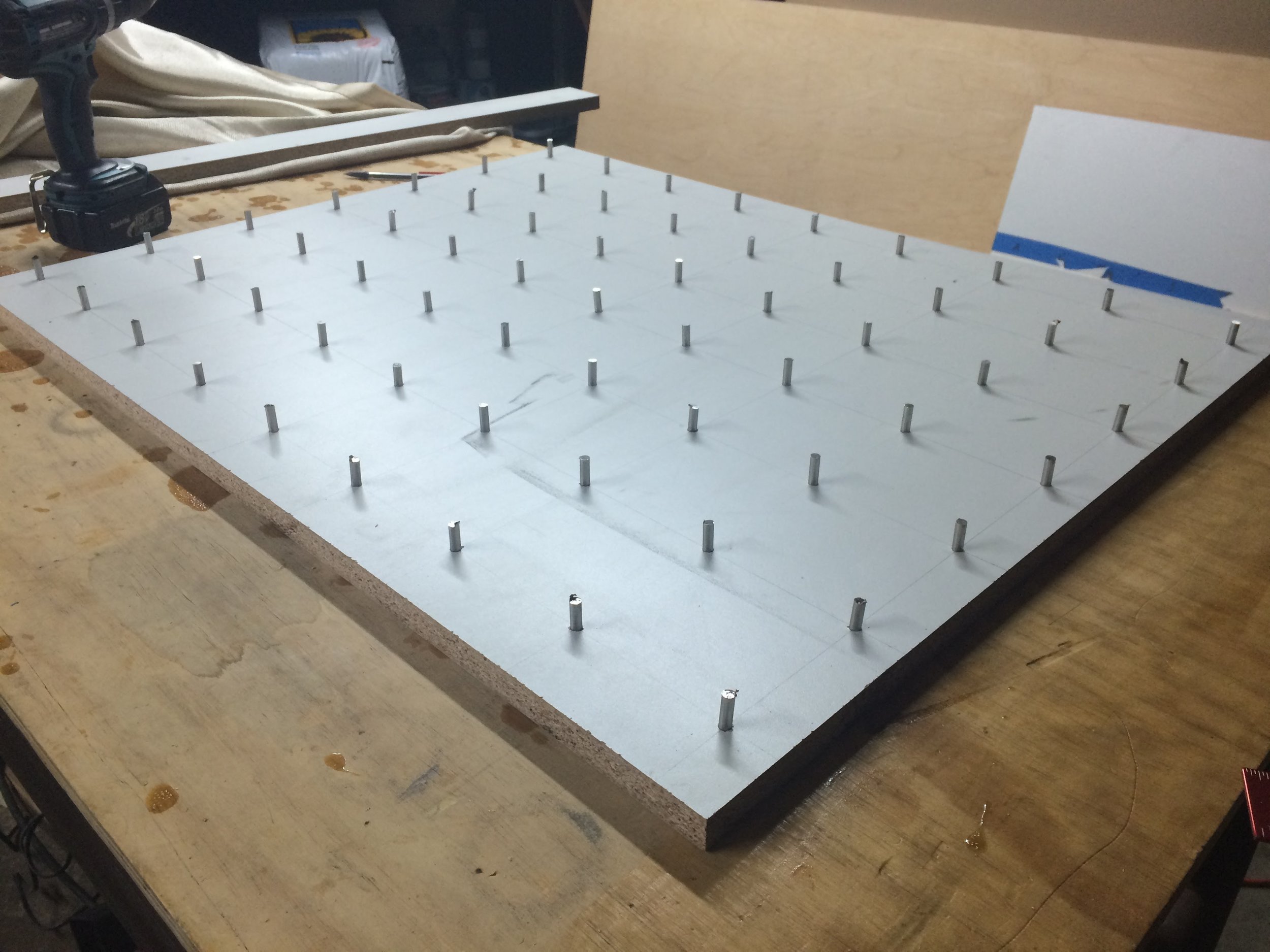

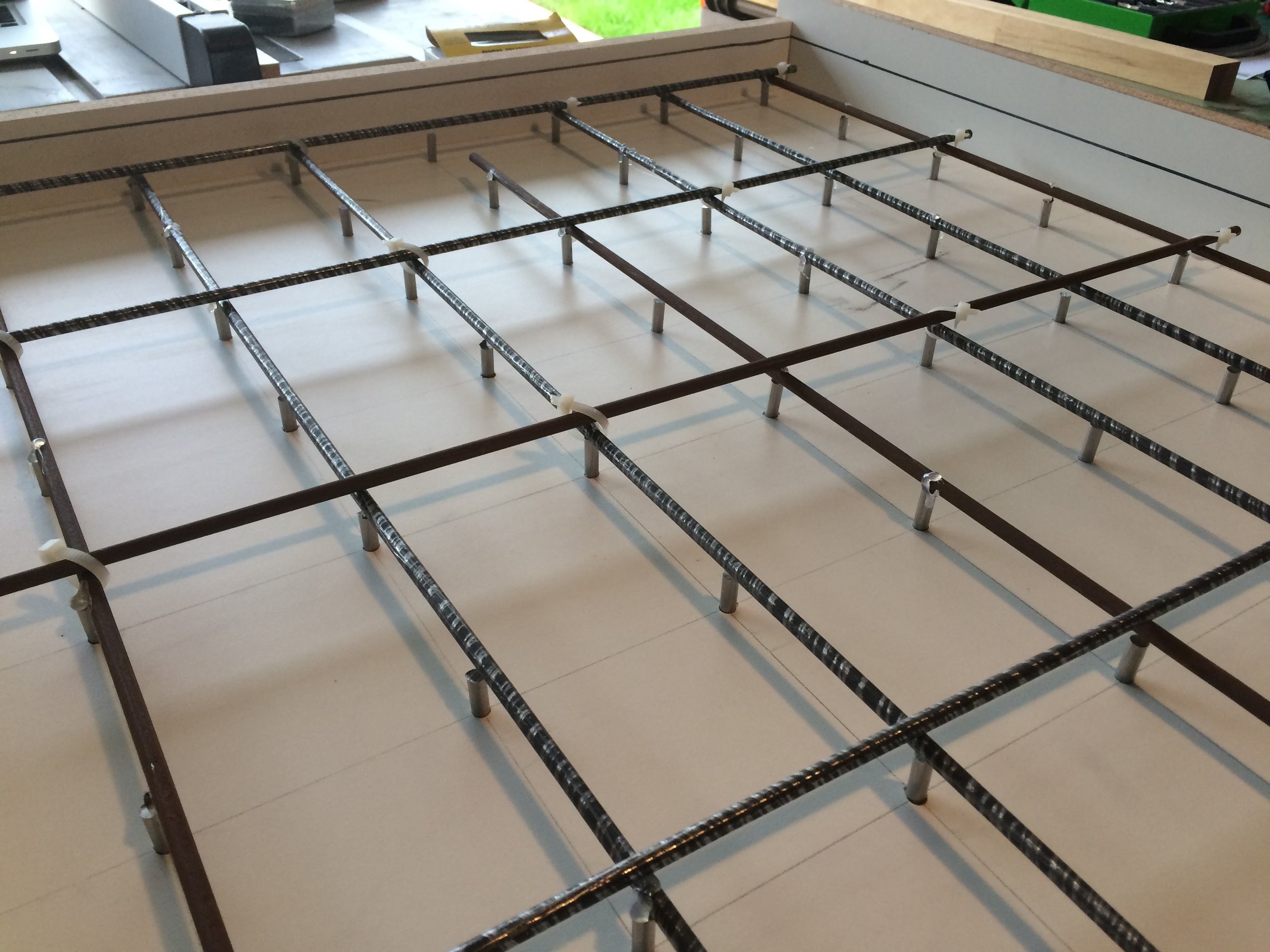

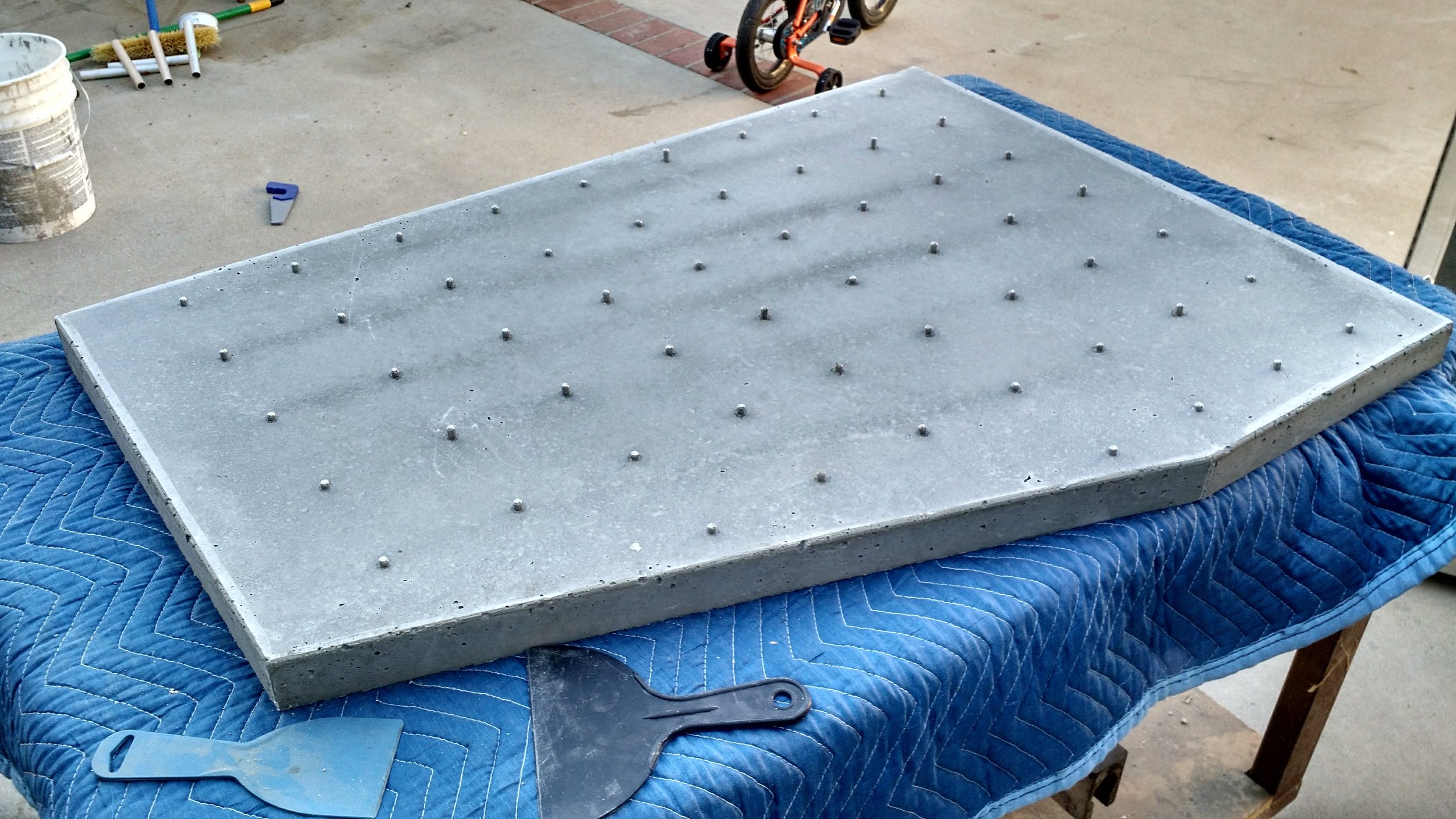

Countertop Process

Creating the countertop was a multistep process. There was creating the layout, creating the mold, grinding stainless steel, polishing, and many coats of food safe sealer. A silicone caulking needed to be applied to the edges as to not let the moisture out as well as creating a clean round over on the edges when released.

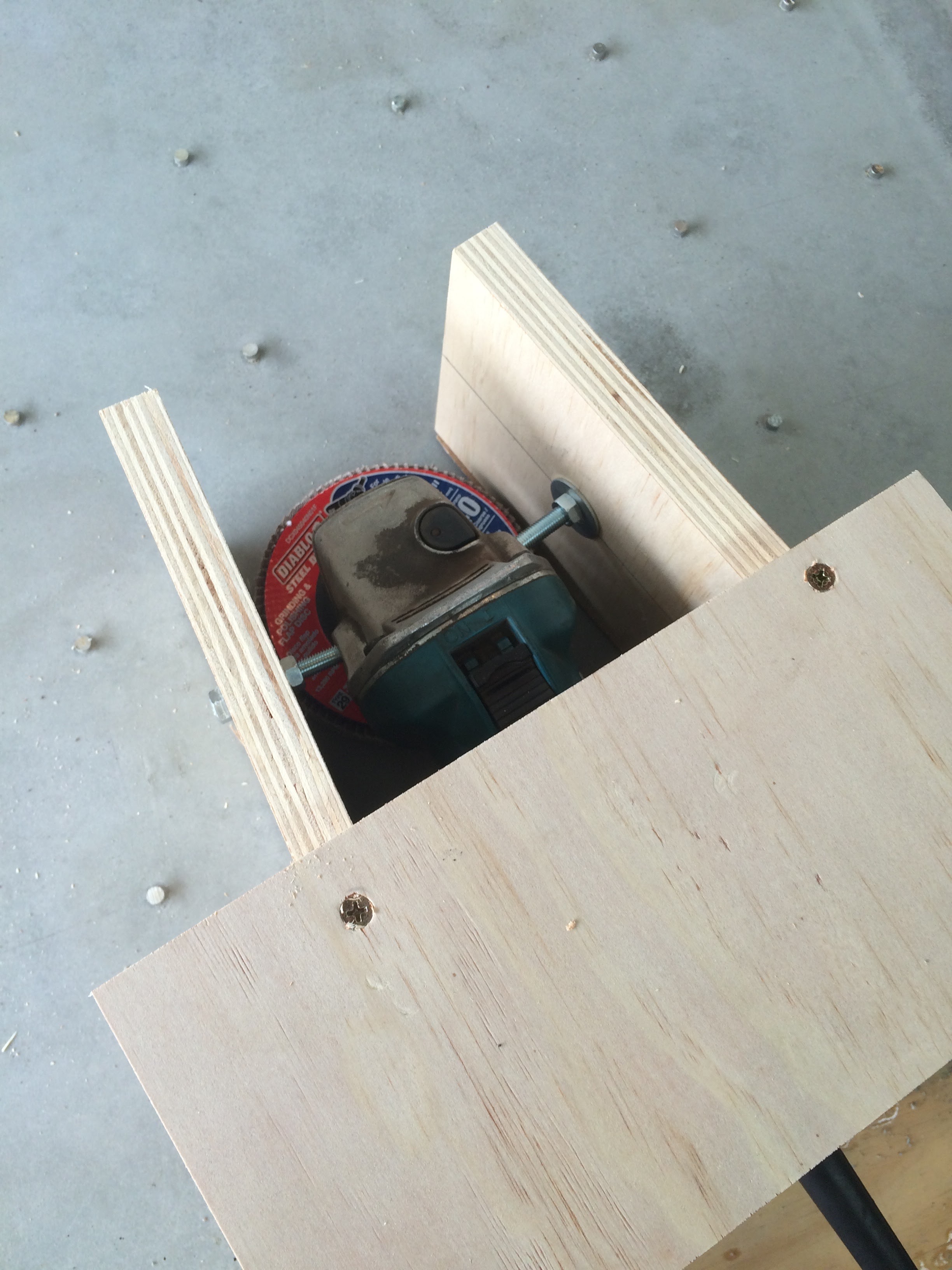

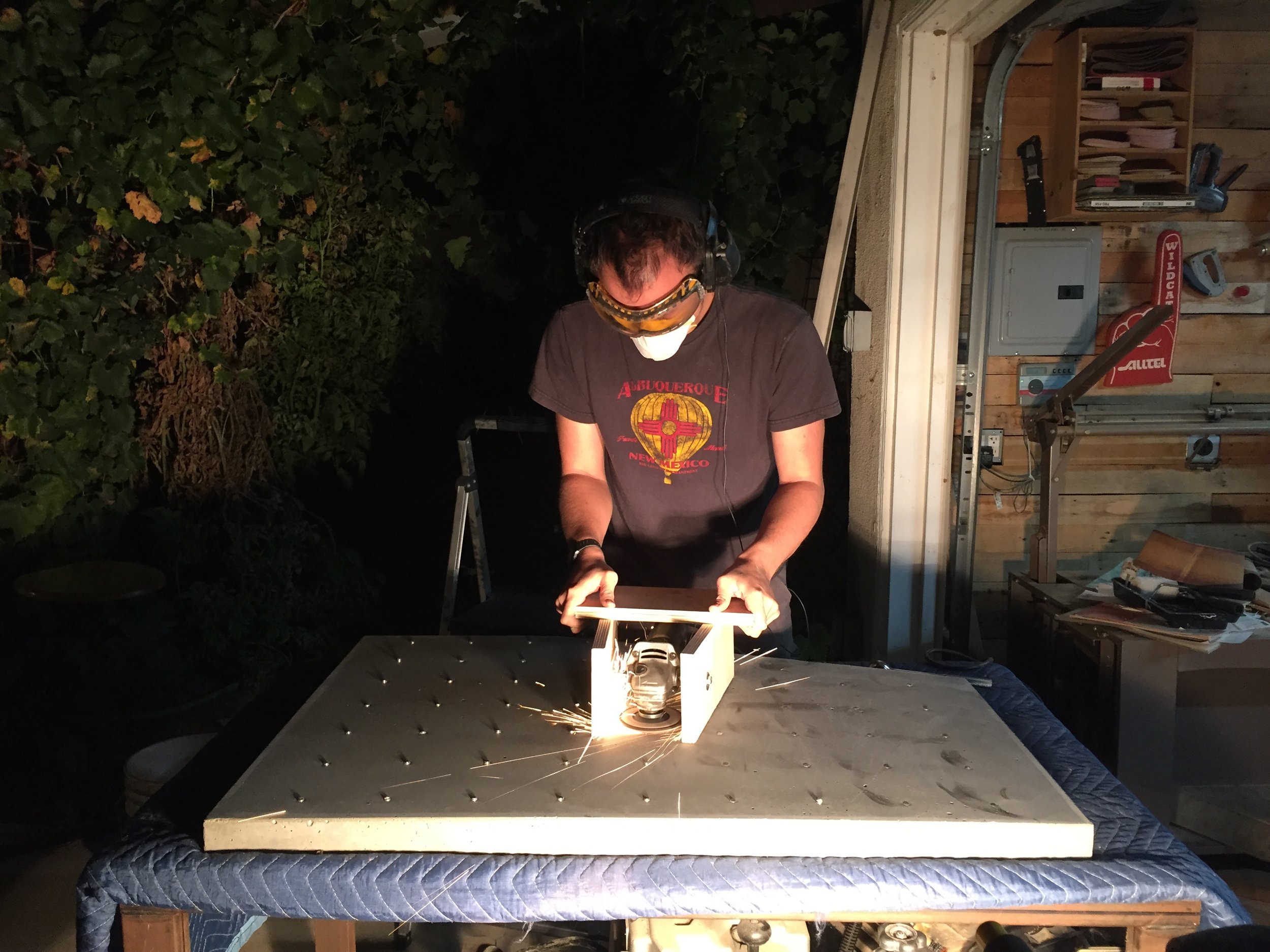

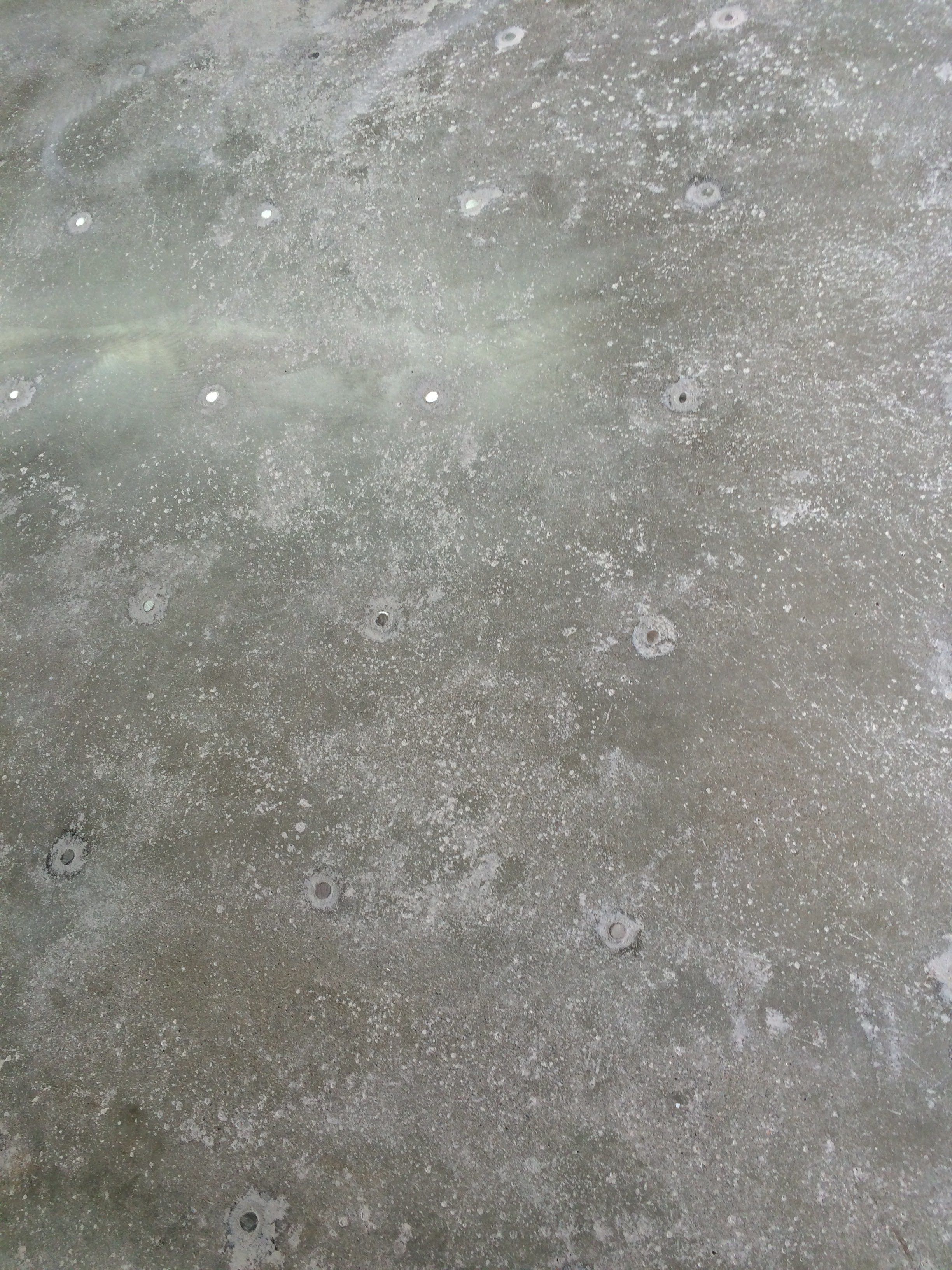

Grinding and Polishing

This process required me to create a custom housing for an existing tool. First, I took off most of the stainless steel bars with an angle grinder. Then I used my custom rig to take down the rest of the stainless bars. I needed to make a tool that would not mar the concrete but would be able to remove the steel. A thin coat of cement was applied to fill in any tiny air bubbles before the coats of sealer were applied.

Creating the shelves

These were not your average shelves. They had an angle on them so that there would be easy access to a breakfast nook. They were also designed to have slides so that there would be storage behind books and make removal of trash easier.

Installation

The install was pretty straight forward. It was just really important all the measurements were very exact. If they were off, the fit and look would not be correct and I would need to start over. When I finished up, the client was very happy with the final product.